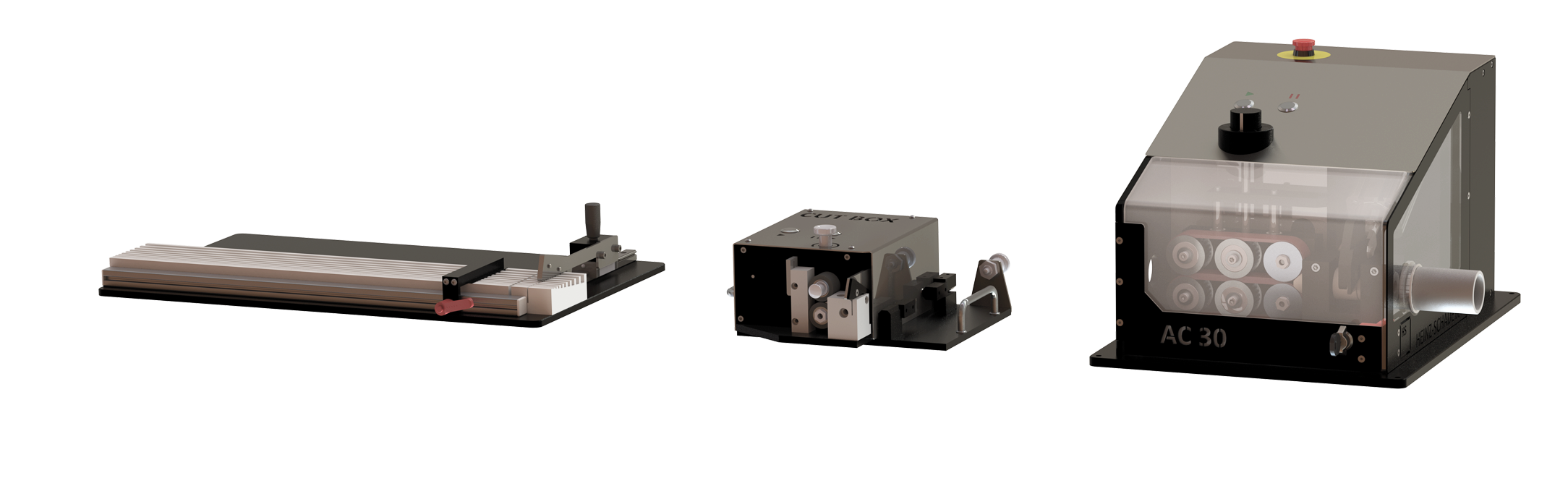

Tube Cutting

Our high-performance cutting machines were developed so as to ensure a very accurate cutting quality. Compact construction, an attractive design and efficient cutting are just some of the benefits of our cutting devices. Our comprehensive assortment of products ranges from the simple manual cutting device to the fully-automatized, highly-sophisticated system with software support which also serves as an assembly workplace.